Work Environment

This occupation is typically found in the following Career Sector(s):

Videos on the Web

- Fitter - Plant Machinery- from: Youtube Search

Most commonly reported Work Activities

- Inspecting Equipment, Structures, or Material Inspecting equipment, structures, or materials to identify the cause of errors or other problems or defects.

- Repairing and Maintaining Mechanical Equipment Servicing, repairing, adjusting, and testing machines, devices, moving parts, and equipment that operate primarily on the basis of mechanical (not electronic) principles.

- Making Decisions and Solving Problems Analysing information and evaluating results to choose the best solution and solve problems.

- Performing General Physical Activities Performing physical activities that require considerable use of your arms and legs and moving your whole body, such as climbing, lifting, balancing, walking, stooping, and handling of materials.

- Communicating with Supervisors, Peers, or Subordinates Providing information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person.

- Getting Information Observing, receiving, and otherwise obtaining information from all relevant sources.

- Handling and Moving Objects Using hands and arms in handling, installing, positioning, and moving materials, and manipulating things.

- Establishing and Maintaining Interpersonal Relationships Developing constructive and cooperative working relationships with others, and maintaining them over time.

- Monitor Processes, Materials, or Surroundings Monitoring and reviewing information from materials, events, or the environment, to detect or assess problems.

- Evaluating Information to Determine Compliance with Standards Using relevant information and individual judgment to determine whether events or processes comply with laws, regulations, or standards.

Working Life

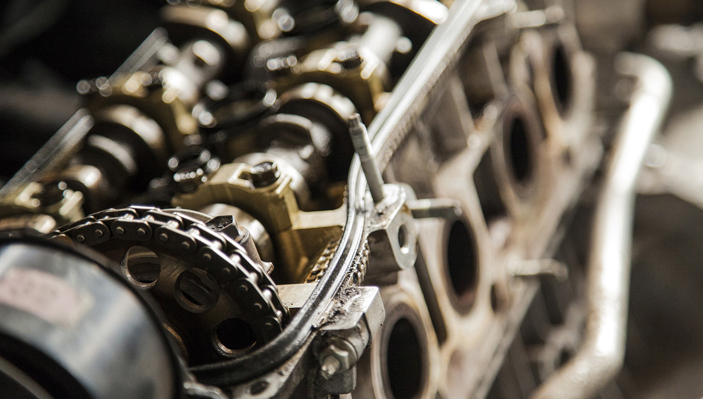

In their work, Mechanical Automation and Maintenance Fitters use lathes, CNC (Computer numerical control), machine tools, drilling and milling machines welding plants.

In plant maintenance, they dismantle and fit new parts and they may also have to make these parts. They also install plant and production equipment and carry out condition monitoring using modern maintenance techniques.

Most commonly reported Work Tasks

- Install or replace machinery, equipment, and new or replacement parts and instruments, using hand or power tools.

- Examine and test machinery, equipment, components, and parts for defects to ensure proper functioning.

- Tend and observe equipment and machinery to verify efficient and safe operation.

- Adjust, connect, or disconnect wiring, piping, tubing, and other parts, using hand or power tools.

- Clean or lubricate vehicles, machinery, equipment, instruments, tools, work areas, and other objects, using hand tools, power tools, and cleaning equipment.

- Hold or supply tools, parts, equipment, and supplies for other workers.

- Diagnose electrical problems and install and rewire electrical components.

- Disassemble broken or defective equipment to facilitate repair and reassemble equipment when repairs are complete.

- Position vehicles, machinery, equipment, physical structures, and other objects for assembly or installation, using hand tools, power tools, and moving equipment.

- Transfer tools, parts, equipment, and supplies to and from work stations and other areas.

Qualities - Fitter - Plant Machinery

You must have strong practical skills and an interest in understanding how machines and control systems function. Good observational skills are required for fault finding. Mechanical Automation and Maintenance Fitters need a logical, methodical approach to problem-solving.

The ability to understand technical information and diagrams is important. You should also be able to write reports of completed repairs.

Interests - Fitter - Plant Machinery

This occupation is typically suited for people with the following Career Interests:

Realist

Realists are usually interested in 'things' - such as buildings, mechanics, equipment, tools, electronics etc. Their primary focus is dealing with these - as in building, fixing, operating or designing them. Involvement in these areas leads to high manual skills, or a fine aptitude for practical design - as found in the various forms of engineering.

Realists like to find practical solutions to problems using tools, technology and skilled work. Realists usually prefer to be active in their work environment, often do most of their work alone, and enjoy taking decisive action with a minimum amount of discussion and paperwork.

Administrative

Administrative people are interested in work that offers security and a sense of being part of a larger process. They may be at their most productive under supervisors who give clear guidelines and while performing routine tasks in a methodical and reliable way.

They tend to enjoy clerical and most forms of office work, where they perform essential administrative duties. They often form the backbone of large and small organisations alike. They may enjoy being in charge of office filing systems, and using computers and other office equipment to keep things running smoothly. They usually like routine work hours and prefer comfortable indoor workplaces.

Investigative

The Investigative person will usually find a particular area of science to be of interest. They are inclined toward intellectual and analytical activities and enjoy observation and theory. They may prefer thought to action, and enjoy the challenge of solving problems with sophiscticated technology. These types prefer mentally stimulating environments and often pay close attention to developments in their chosen field.

Entry / Progression - Fitter - Plant Machinery

There are many pathways for you to develop the skills & qualifications to progress in a career as a Manufacturing Automation Fitter.

Sample Education and Training Pathways

A number of courses are available throughout the country that focus on learning and skills that may be useful for this career. The examples and links below may guide you in your research.

Further Education (FET)

Further Education & Training (FET) Courses are delivered by local ETBs, ranging in duration from several weeks up to 20 months. Courses are designed to meet the labour market needs and often include a large element of work experience.

Example search terms include: engineering, operations.

Search for FET Courses

PLC Courses (FET)

PLC courses are full-time courses, one or two years duration, with awards at Level 5 and 6 on the NFQ. They are offered nationally in Schools and Colleges of Further Education.

Example search terms include: engineering.

Search for PLC Courses

Apprenticeships:

Apprenticeships are structured work-based training programs that combine on-the-job training with classroom instruction. They run from 2 – 4 years and are open to individuals of all ages, including school leavers, those seeking a career change, and existing employees who wish to upskill.

Examples: Manufacturing Automation Fitter.

To become an apprentice, you must obtain employment as an apprentice in your chosen occupation.

The employer must be approved to train apprentices. The employer must register you as an apprentice within two weeks of recruitment. In certain crafts, apprenticeship applicants are required to pass a colour vision test approved by SOLAS.

Entry Requirements: The minimum age at which the employment of an apprentice may commence is 16 years of age.

The minimum educational requirements are:

- Grade D in five subjects in the Department of Education & Skills Junior Certificate Examination or an approved equivalent, OR

- The successful completion of an approved pre-apprenticeship course, OR

- Three years work experience gained over sixteen years of age in a relevant designated industrial activity as SOLAS shall deem acceptable.

It should be noted that these are the current approved minimum educational requirements for apprenticeship programmes, however, previous experience of the following subjects would be an advantage but not essential: Metalwork, Physics, Engineering, Technology, Mathematics and Technical Drawing/Graphics.

Search for Apprenticeships

Higher Education CAO (Undergraduate)

Higher Education courses at Levels 6 to 8 on the NFQ, delivered in Universities and Technological Universities & Institutes. Courses run from 2 – 5 years and places are allocated on a points-based system, processed by the Central Application Office.

Example search terms include: engineering.

Opportunities exists to explore a technical university or an institute of technology course via CAO.

Search for CAO Courses

Pay & Salary - Fitter - Plant Machinery

Salary Range (thousands per year)* €35k - €65k

Salaries vary based on employer, location, experience, duties, and role.

Data Source(s):

Indeed/ Morgan McKinley/ CPL/ Glassdoor/ Excel

Last Updated: March, 2024

Labour Market Updates - Fitter - Plant Machinery

Useful Contacts - Fitter - Plant Machinery

-

Engineers Ireland

- 22 Clyde Road, Ballsbridge Dublin 4

- (01) 665 1300

- Click Here