Work Environment

This occupation is typically found in the following Career Sector(s):

Videos & Interviews

Phelim Reilly, Process Engineer / Toolmaker

Phelim began his career as a toolmaker apprentice and progressed on to working as a Process Engineer with Belurgen Precision Engineering Ltd. Phelim gives an overview of the different apprenticeship phases and the importance of learning from working with others who have already gone through the process.

Videos on the Web

- Toolmaker / CNC Programmer- from: Youtube Search

Most commonly reported Work Activities

- Getting Information Observing, receiving, and otherwise obtaining information from all relevant sources.

- Making Decisions and Solving Problems Analysing information and evaluating results to choose the best solution and solve problems.

- Communicating with Supervisors, Peers, or Subordinates Providing information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person.

- Thinking Creatively Developing, designing, or creating new applications, ideas, relationships, systems, or products, including artistic contributions.

- Monitor Processes, Materials, or Surroundings Monitoring and reviewing information from materials, events, or the environment, to detect or assess problems.

- Controlling Machines and Processes Using either control mechanisms or direct physical activity to operate machines or processes (not including computers or vehicles).

- Repairing and Maintaining Mechanical Equipment Servicing, repairing, adjusting, and testing machines, devices, moving parts, and equipment that operate primarily on the basis of mechanical (not electronic) principles.

- Drafting, Laying Out, and Specifying Technical Devices, Parts, and Equipment Providing documentation, detailed instructions, drawings, or specifications to tell others about how devices, parts, equipment, or structures are to be fabricated, constructed, assembled, modified, maintained, or used.

- Updating and Using Relevant Knowledge Keeping up-to-date technically and applying new knowledge to your job.

- Organising, Planning, and Prioritising Work Developing specific goals and plans to prioritise, organise, and accomplish your work.

Working Life

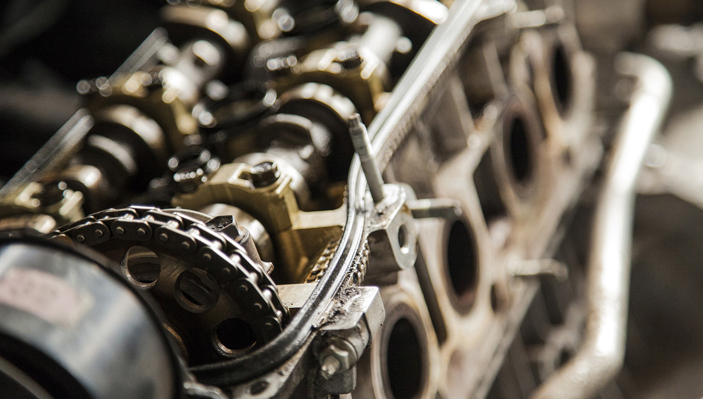

Toolmakers work to high specifications and quality requirements to produce machine tools used in manufacturing. Manufacturing industries use the tools to make a very diverse range of parts and products, from dashboards to pen tops, to central heating boilers. Toolmakers also make moulds to form shapes, jigs to guide cutters or hold a part in place, and dies, which are shaped blocks that are used to cut, stamp or press materials.

At the beginning of their work, toolmakers may use technical drawings to learn about the product. Next, they operate a range of specialist engineering machines such as lathes, Computer Numerical Controlled (CNC) machines, and grinding, milling and boring machines.

Toolmakers use hand tools like files, and small machines like grinding and polishing machines to smooth and finish a tool. When they are satisfied with the tool, the toolmaker fits it onto the production machine and supervises a test run.

They normally wear safety clothing such as overalls, and hearing and eye protectors when necessary.

Most commonly reported Work Tasks

- Verify dimensions, alignments, and clearances of finished parts for conformance to specifications, using measuring instruments such as calipers, gauge blocks, micrometers, or dial indicators.

- Set up and operate conventional or computer numerically controlled machine tools such as lathes, milling machines, or grinders to cut, bore, grind, or otherwise shape parts to prescribed dimensions and finishes.

- Visualise and compute dimensions, sises, shapes, and tolerances of assemblies, based on specifications.

- Study blueprints, sketches, models, or specifications to plan sequences of operations for fabricating tools, dies, or assemblies.

- Fit and assemble parts to make, repair, or modify dies, jigs, gauges, and tools, using machine tools, hand tools, or welders.

- Inspect finished dies for smoothness, contour conformity, and defects.

- Select metals to be used from a range of metals and alloys, based on properties such as hardness or heat tolerance.

- Lift, position, and secure machined parts on surface plates or worktables, using hoists, vises, v-blocks, or angle plates.

- File, grind, shim, and adjust different parts to properly fit them together.

- Smooth and polish flat and contoured surfaces of parts or tools, using scrapers, abrasive stones, files, emery cloths, or power grinders.

Further Information

- Toolmaker- from: N.C.S. [UK]

Qualities - Toolmaker / CNC Programmer

Producing high levels of accuracy demands patience and concentration. You need to be able to read, understand and analyse engineering drawings. Good number skills are important to make precise measurements and calculations.

A practical approach to problem-solving is necessary. You need to work logically and plan your work.

Co-ordination and hand skills are important for using a wide range of machine tools, hand tools and other equipment. Many toolmakers work alone, so you may need to work effectively without supervision.

Toolmakers spend much of their time on their feet and need to be fairly fit and active.

Interests - Toolmaker / CNC Programmer

This occupation is typically suited for people with the following Career Interests:

Realist

Realists are usually interested in 'things' - such as buildings, mechanics, equipment, tools, electronics etc. Their primary focus is dealing with these - as in building, fixing, operating or designing them. Involvement in these areas leads to high manual skills, or a fine aptitude for practical design - as found in the various forms of engineering.

Realists like to find practical solutions to problems using tools, technology and skilled work. Realists usually prefer to be active in their work environment, often do most of their work alone, and enjoy taking decisive action with a minimum amount of discussion and paperwork.

Investigative

The Investigative person will usually find a particular area of science to be of interest. They are inclined toward intellectual and analytical activities and enjoy observation and theory. They may prefer thought to action, and enjoy the challenge of solving problems with sophiscticated technology. These types prefer mentally stimulating environments and often pay close attention to developments in their chosen field.

Administrative

Administrative people are interested in work that offers security and a sense of being part of a larger process. They may be at their most productive under supervisors who give clear guidelines and while performing routine tasks in a methodical and reliable way.

They tend to enjoy clerical and most forms of office work, where they perform essential administrative duties. They often form the backbone of large and small organisations alike. They may enjoy being in charge of office filing systems, and using computers and other office equipment to keep things running smoothly. They usually like routine work hours and prefer comfortable indoor workplaces.

Entry / Progression - Toolmaker / CNC Programmer

There are many pathways to develop your skills, experience, and qualifications for a carer in toolmaking and Original Equipment Manufacture [OEM].

Sample Education and Training Pathways

A number of courses are available throughout the country that focus on learning and skills that may be useful for this career. The examples and links below may guide you in your research.

Further Education (FET)

Further Education & Training (FET) Courses are delivered by local ETBs, ranging in duration from several weeks up to 20 months. Courses are designed to meet the labour market needs and often include a large element of work experience.

Example search terms include: engineering operations, precision manufacturing.

Search for FET Courses

PLC Courses (FET)

PLC courses are full-time courses, one or two years duration, with awards at Level 5 and 6 on the NFQ. They are offered nationally in Schools and Colleges of Further Education.

Example search terms include: engineering, pre-apprenticeship, manufacturing.

Search for PLC Courses

Apprenticeships:

Apprenticeships are structured work-based training programs that combine on-the-job training with classroom instruction. They run from 2 – 4 years and are open to individuals of all ages, including school leavers, those seeking a career change, and existing employees who wish to upskill.

Examples: Toolmaking, OEM.

Search for Apprenticeships

To become an apprentice in Ireland you must be hired by an employer. Apprenticeship employers are formally approved by SOLAS in advance of employing apprentices. Apprentices get a formal contract of employment as part of their apprenticeship.

To find an apprenticeship, you can search apprenticeship vacancies on the Apprenticeship Jobs Portal. You can search for vacancies by location and by apprenticeship.

Entry Requirements

The minimum age at which the employment of an apprentice may commence is 16 years of age.

The minimum educational requirements are:

- Grade D in five subjects in the Department of Education & Skills Junior Certificate Examination or an approved equivalent, or

- The successful completion of an approved pre-apprenticeship course, or

- Three years’ work experience gained over sixteen years of age in a relevant designated industrial activity as SOLAS shall deem acceptable.

It should be noted that these are the current approved minimum educational requirements for apprenticeship programmes, however, previous experience of the following subjects would be an advantage but not essential: Metalwork, Physics, Engineering, Technology, Mathematics and Technical Drawing/Graphics.

Full eligibility criteria for this apprenticeship are available in the Toolmaking Apprenticeship brochure, OEM Apprenticeship NFQ level 6, Metal Fabrication NFQ level 6

Pay & Salary - Toolmaker / CNC Programmer

Salary Range (thousands per year)* €30k - €55k

Salaries vary based on employer, location, experience, duties, shift pattern, and role.

Data Source(s):

Indeed/ Payscale / Solas / Morgan McKinley/ Osborne/ Sigmar

Last Updated: March, 2024

Labour Market Updates - Toolmaker / CNC Programmer

Note: The following information relates to occupations that include: Metal machining setters; Setter-operators; Tool makers; tool fitters and markers-out; Metal working production and maintenance fitters; Precision instrument makers; Precision instrument repairers; Air-conditioning and refrigeration engineers, smiths and forge workers; farriers; core makers (metal trades); moulders (metal trades); die casters; sheet metal workers; sheet metal fabricators; panel beaters (metal trades)

This information has been derived from the Solas National Skills Bulletin (2023).

Although the five-year annual average growth for this occupation was negative, the number of persons employed was more than a third higher than the pre-COVID-19 level. Vacancies for computer numerical control (CNC) programmers and operators occurred frequently in the DSP Jobs Ireland data and were also the main roles for which employment permits were issued for this occupational group. Demand for this occupation was evident in the Skills for Growth data, in particular for qualified CNC operators, toolmakers, and maintenance fitters, with demand mostly, although not exclusively, related to high-tech manufacturing (i.e. medtech, pharma); skills in demand for this occupation included problem solving, communications, digital, and lean processing skills.

The higher than average share of persons employed aged 55 years and older also indicates that replacement demand is likely to create job opportunities for these roles. Although shortages of CNC programmers persist, they are considered niche and most likely affecting small and medium sized firms in particular. With different types of tasks associated with CNC programming work, some are more exposed to automation than others, depending on the type of machinery used.

Useful Contacts - Toolmaker / CNC Programmer

-

Engineers Ireland

- 22 Clyde Road, Ballsbridge Dublin 4

- (01) 665 1300

- Click Here

-

Construction Industry Federation