Work Environment

This occupation is typically found in the following Career Sector(s):

Videos & Interviews

Peter LaComber, Consulting Engineer

Peter LaComber graduated from UCD as a Mechanical Engineer and is working as a Senior Consulting Engineer for Irish Cement. He has held a variety of roles over the last 11 years in the company and is now Plant Liaison Manager for the Kiln 3 construction project in Drogheda.

Rebecca Tighe, Process Engineer

Rubecca graduated from TCD with a degree in Mechanical and Manufacturing Engineering. She applied to Intel after leaving college through their online jobs applications system, and successfully secured a job as a Process Engineer. Now she works in the hi-tech clean rooms producing the computer chips used everyday across the globe.

Videos on the Web

- Manufacturing Engineer- from: Youtube Search

- Manufacturing Engineer- from: icould [UK] Video

- Principal Manufacturing Engineer- from: icould [UK] Video

Most commonly reported Work Activities

- Making Decisions and Solving Problems Analysing information and evaluating results to choose the best solution and solve problems.

- Getting Information Observing, receiving, and otherwise obtaining information from all relevant sources.

- Interacting With Computers Using computers and computer systems (including hardware and software) to program, write software, set up functions, enter data, or process information.

- Communicating with Supervisors, Peers, or Subordinates Providing information to supervisors, co-workers, and subordinates by telephone, in written form, e-mail, or in person.

- Analysing Data or Information Identifying the underlying principles, reasons, or facts of information by breaking down information or data into separate parts.

- Processing Information Compiling, coding, categorising, calculating, tabulating, auditing, or verifying information or data.

- Identifying Objects, Actions, and Events Identifying information by categorising, estimating, recognising differences or similarities, and detecting changes in circumstances or events.

- Monitor Processes, Materials, or Surroundings Monitoring and reviewing information from materials, events, or the environment, to detect or assess problems.

- Drafting, Laying Out, and Specifying Technical Devices, Parts, and Equipment Providing documentation, detailed instructions, drawings, or specifications to tell others about how devices, parts, equipment, or structures are to be fabricated, constructed, assembled, modified, maintained, or used.

- Documenting/Recording Information Entering, recording, storing, or maintaining information in written or electronic/magnetic form.

Working Life

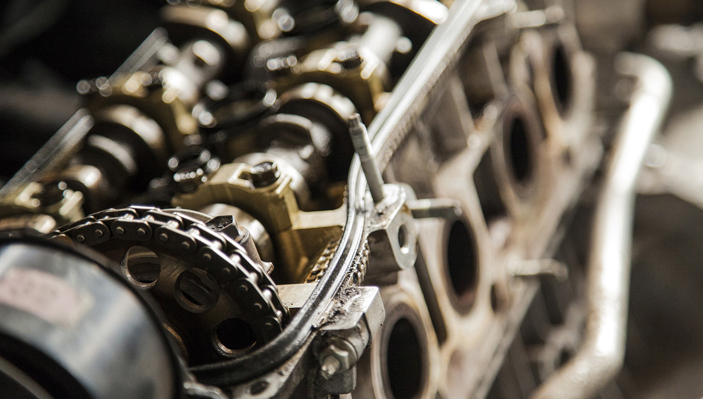

Modern manufacturing systems are large and complex. Advanced manufacturing production plants are made up of tightly or loosely connected building blocks.

Manufacturing engineers are responsible for the smooth running of a system as a whole. They may be involved at all stages of the system, including research and design, manufacturing, repairs, maintenance and marketing or they may be assigned to one particular area. Manufacturing engineering isn't just about knowledge of different engineering disciplines - it is about making manufacturing systems work by taking account of all the factors involved. These include specifications and targets, the evolution of systems over time, the processes and methods involved, and economic, safety and quality considerations.

Manufacturing engineers usually have an in-depth knowledge of one specialist area, although it is essential that they have a broad knowledge of many subjects. They will apply this knowledge to making the production process as efficient as possible, maximising yield and reducing production time

They need a broad knowledge because they often work on projects involving engineers from different backgrounds. Manufacturing engineers have a wide-ranging involvement at all stages of the production cycle, from the initial planning of a facility to its day to day operations right through to the steps involved in its closing. This means they take account of many factors, from the materials used to the automated production technologies used down to packaging and distribution.

Most commonly reported Work Tasks

- Troubleshoot new or existing product problems involving designs, materials, or processes.

- Investigate or resolve operational problems, such as material use variances or bottlenecks.

- Identify opportunities or implement changes to improve manufacturing processes or products or to reduce costs, using knowledge of fabrication processes, tooling and production equipment, assembly methods, quality control standards, or product design, materials and parts.

- Apply continuous improvement methods such as lean manufacturing to enhance manufacturing quality, reliability, or cost-effectiveness.

- Provide technical expertise or support related to manufacturing.

- Incorporate new manufacturing methods or processes to improve existing operations.

- Review product designs for manufacturability or completeness.

- Determine root causes of failures or recommend changes in designs, tolerances, or processing methods, using statistical procedures.

- Prepare reports summarising information or trends related to manufacturing performance.

- Prepare documentation for new manufacturing processes or engineering procedures.

Further Information

- Engineer, manufacturing and production- from: GradIreland

- Industrial & Manufacturing Engineering- from: STEPS

- Manufacturing Systems Engineer- from: N.C.S. [UK]

Qualities - Manufacturing Engineer

If you enjoy sorting out problems by taking an overview and looking at all the different factors, manufacturing engineering could be worth thinking about as a career. You should also enjoy organising work and other activities into manageable chunks so that you get effective results. You should possess good analytical skills.

As well as being methodical and creative, it's just as important to have good interpersonal skills. If you've got leadership potential it will come in very useful in systems engineering. You should also enjoy working as part of a team and have good computer skills

Interests - Manufacturing Engineer

This occupation is typically suited for people with the following Career Interests:

Realist

Realists are usually interested in 'things' - such as buildings, mechanics, equipment, tools, electronics etc. Their primary focus is dealing with these - as in building, fixing, operating or designing them. Involvement in these areas leads to high manual skills, or a fine aptitude for practical design - as found in the various forms of engineering.

Realists like to find practical solutions to problems using tools, technology and skilled work. Realists usually prefer to be active in their work environment, often do most of their work alone, and enjoy taking decisive action with a minimum amount of discussion and paperwork.

Investigative

The Investigative person will usually find a particular area of science to be of interest. They are inclined toward intellectual and analytical activities and enjoy observation and theory. They may prefer thought to action, and enjoy the challenge of solving problems with sophiscticated technology. These types prefer mentally stimulating environments and often pay close attention to developments in their chosen field.

Administrative

Administrative people are interested in work that offers security and a sense of being part of a larger process. They may be at their most productive under supervisors who give clear guidelines and while performing routine tasks in a methodical and reliable way.

They tend to enjoy clerical and most forms of office work, where they perform essential administrative duties. They often form the backbone of large and small organisations alike. They may enjoy being in charge of office filing systems, and using computers and other office equipment to keep things running smoothly. They usually like routine work hours and prefer comfortable indoor workplaces.

Entry / Progression - Manufacturing Engineer

Manufacturing engineers have typically completed an appropriate engineering degree, generally at honours level. A masters qualification (M.Eng) may also be required.

Manufacturing engineers come from a wide variety of engineering backgrounds, including electrical and electronic, mechanical, chemical, telecommunications and aeronautical engineering.

There are many pathways to building up skills & qualifications to progress towards a career in engineering.

Sample Education and Training Pathways

A number of courses are available throughout the country that focus on learning and skills that may be useful for this career. The examples and links below may guide you in your research.

Further Education (FET)

Further Education & Training (FET) Courses are delivered by local ETBs, ranging in duration from several weeks up to 20 months. Courses are designed to meet the labour market needs and often include a large element of work experience.

Example search terms include: engineering technology, engineering operations, manufacturing technician maintenance skills technology, CNC, computer numeric control operator, life sciences, manufacturing operations.

Search for FET Courses

PLC Courses (FET)

PLC courses are full-time courses, one or two years duration, with awards at Level 5 and 6 on the NFQ. They are offered nationally in Schools and Colleges of Further Education.

Example search terms include: pre-apprenticeship engineering, pre university engineering, engineering technology.

Search for PLC Courses

Apprenticeships:

Apprenticeships are structured work-based training programs that combine on-the-job training with classroom instruction. They run from 2 – 4 years and are open to individuals of all ages, including school leavers, those seeking a career change, and existing employees who wish to upskill.

Examples: Engineering, Manufacturing, Design.

Search for Apprenticeships

Higher Education CAO (Undergraduate)

Higher Education courses at Levels 6 to 8 on the NFQ, delivered in Universities and Technological Universities & Institutes. Courses run from 2 – 5 years and places are allocated on a points-based system, processed by the Central Application Office.

Example search terms include: manufacturing, design engineering, manufacturing engineering, mechanical, agricultural, biomedical, energy, automation engineering.

Search for CAO Courses

Springboard courses you can study full, part time, and online blended engineering & manufacturing programmes to develop your skills search Springboard courses.

Higher Education (Postgraduate)

Postgraduate courses are courses at Levels 9 and 10 on the NFQ and usually last 1 – 2 years full time, or longer if a PhD or part time. Entrants typically require an undergraduate award (Level 8).

Example search terms include: digitalisation of manufacturing, research, engineering, mechanical, manufacturing, process, automation systems, biomedical, leadership in digitisation of manufacturing, pharmaceutical manufacturing technology, smart manufacturing technology, quality management.

Search for Postgraduate Courses

Professional Development

Professional development (CPD) courses are specialised training, formal education, or advanced professional learning that improves skills, professional knowledge, competency, and overall effectiveness in the professional world.

Check the Useful Contacts tab on this page to see if there are any professional bodies listed who may provide training related to this career.

Pay & Salary - Manufacturing Engineer

Salary Range (thousands per year)* €40k - €75k

Salaries vary based on employer, location, experience, duties, and role.

Data Source(s):

Morgan McKinley/ CPL/ Collins McNicolas/ Sigmar/ Azon/ Brightwater

Last Updated: July, 2024

Labour Market Updates - Manufacturing Engineer

Note: The following information relates to occupations that include: Mechanical engineers; Electrical engineers; Electronics engineers; Engineering professionals n.e.c.

This information has been derived from the Solas National Skills Bulletin (2023).

Despite a strong five-year annual average employment growth rate, the numbers employed declined marginally between 2021 and 2022. Over half (55%) were employed in the professional activities sector with the remainder spread across industry and other sectors. The number of employment permits issued in 2022 grew strongly (and remained strong in the first five months of 2023) in roles including electrical, mechanical, automation, and validation engineers. There is evidence in the Recruitment Agency Survey of difficulties in filling vacancies for roles in electrical, automation, mechanical, and environmental health & safety (EHS) engineers.

Skills for Growth and Spotlight on Skills data highlight issues with sourcing mechanical, automation and process engineers, with project management, Lean Six Sigma, and CAD/AutoCAD skills in particular demand for these roles. Despite a 3% fall in 2022, this occupation was amongst the most frequently mentioned in online job adverts. Overall demand for this occupation may moderate, although this may be offset by any increase in the extension of Industry 4.0 and Industry 5 technologies to more traditional manufacturing sectors and smaller sized companies; in addition, increased activity associated with the generation of green energy (mechanical/electrical) will also drive demand for these skills. As such, difficulty in sourcing suitably qualified and experienced engineers is expected to continue, albeit in smaller numbers.

Useful Contacts - Manufacturing Engineer

-

Engineers Ireland

- 22 Clyde Road, Ballsbridge Dublin 4

- (01) 665 1300

- Click Here